Submit feedback

How Is New-Gen Molds Technology Powering Future Vehicle Designs?

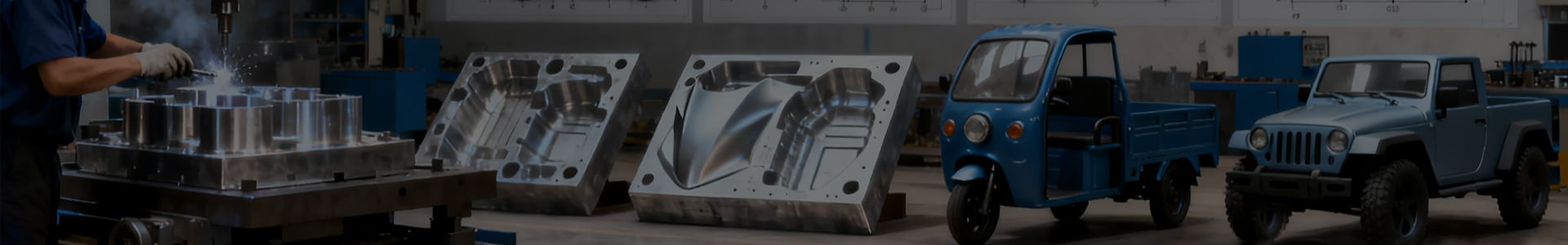

In the fast-changing world of mobility manufacturing, innovation has become the key driving force behind the development of vehicle exterior molds for both three-wheeled vehicles and four-wheeled vehicles. As brands race to launch new models, improve design flexibility, and meet the rising demand for electric mobility, mold manufacturers must deliver faster, more precise, and more modular solutions.

Lingfei Molding is cycling this transition with a progressive approach to mold engineering—combining modular design, digital simulation, and high-precision machining to help manufacturers achieve shorter development cycles, better product quality, and greater production stability.

Why Modular Mold Design Is Transforming Exterior Part Development?

One of Lingfei Molding's strongest advantages is its flexible, modular mold design philosophy. As vehicle models evolve more rapidly—especially in the booming markets of electric three-wheeled and four-wheeled vehicles—traditional mold development cycles can no longer keep up. Manufacturers need more adaptable solutions that support frequent exterior design adjustments without compromising quality.

(1) Benefits of Lingfei's Modular Mold System:

- Shorter development timelines for new vehicle models

- Lower engineering and redesign costs

- Rapid prototype-to-production conversion

- Easy adaptation for vehicle variants and upgrades

This flexibility is particularly valuable for lightweight vehicles whose styling and body structures change frequently due to new features, functional upgrades, and consumer expectations.

Applications in Three-Wheeled Vehicles

Manufacturers of three-wheeled vehicles—often used for last-mile delivery, commercial logistics, or personal mobility—require mold designs that adapt easily to multiple exterior configurations:

- Streamlined front fairings

- Weather-resistant cargo shells

- Aerodynamic canopy structures

- Branding-ready exterior panels

Lingfei's modular solutions reduce engineering workload while enabling faster turnaround for each model variation.

(2) Applications in Four-Wheeled Vehicles

Four-wheeled lightweight EVs and neighborhood electric vehicles need exterior molds capable of supporting:

- Continuous design refreshes

- Improved aerodynamic performance

- Integrated lighting and sensor housings

- Enhanced crash protection

Modular molds help OEMs stay competitive by enabling more frequent model updates without high costs.

(3) Engineering Powered by Equipment

Beyond design flexibility, Lingfei Molding excels in manufacturing accuracy. The company utilizes five-axis machining centers with deep-hole drilling capability, allowing for precise processing of large and structurally complex molds.

- Why Five-Axis Technology Matters for Vehicle Exterior Molds

- Enables machining of complex geometries with fewer setups

- Improves dimensional accuracy for large mold bases

- Ensures uniform placement of internal cooling channels

- Strengthens mold durability and structural stability

For large exterior parts—such as bumpers, front covers, roof shells, and side enclosures—five-axis precision is essential to ensure consistent production results and good part surface quality.

(4) Common Exterior Parts Produced with Lingfei Molding

| Vehicle Type | Typical Exterior Molded Parts | Key Performance Requirements |

| Three-wheeled Vehicle | Front covers, cargo shells, side panels, fenders | Lightweight, durable, stable under vibration |

| Four-wheeled Vehicle | Bumpers, body panels, door skins, tailgate trims | High precision, smooth finish, structural rigidity |

| Utility EVs | Protective housings, rear enclosures, and roof panels | Impact resistance, modular design, weatherproofing |

These components must meet stringent standards for structural integrity, surface appearance, and assembly accuracy—standards that Lingfei's high-precision molds consistently deliver.

(5) Digital Mold Engineering Improves Exterior Part Quality

Lingfei integrates a digital-early workflow throughout mold development. By using simulations and engineering analysis, the company optimizes mold performance long before machining begins.

Core Digital Engineering Capabilities

- Mold-flow analysis to predict filling patterns and prevent defects

- Thermal optimization for faster, more stable cooling

- Stress simulation to ensure mold strength and longevity

- Surface texture engineering for premium visual finishes

This great engineering lowers trial-and-error time during sampling while ensuring high-quality exterior components for vehicle manufacturers.

(6) Lightweight Materials Support the EV Mobility Trend

Lightweight engineering is becoming essential as three-wheeled and four-wheeled electric vehicles continue to gain global market traction. Lingfei Molding supports a full range of great lightweight plastics, including:

- PP (Polypropylene)

- ABS

- PC/ABS blends

- Glass-fiber reinforced materials

- TPO for exterior trims

Why Lightweight Materials Matter

- Improved energy efficiency and extended EV battery life

- Enhanced vehicle handling and stability

- Greater flexibility for aerodynamic exterior styling

- Strong impact resistance without excessive weight

Lingfei's mold designs are optimized to fully support the flow and cooling characteristics of these materials, ensuring consistent part quality in high-volume production.

(7) Customization Capabilities for Commercial Applications

The commercial vehicle sector—especially in last-mile delivery—relies heavily on customizable exterior shells. Lingfei's modular mold system allows brands to tailor exterior components to unique industry needs.

- Examples of Custom Exterior Requirements

- Different cargo box capacities

- Weatherproof delivery enclosures

- Panels designed for large advertising graphics

- Reinforced protective covers for rough environments

- Modular door and window configurations

With Lingfei's solutions, manufacturers can introduce new product variations without long cycle times or excessive tooling costs.

(8) Precision Molds Improve Assembly Consistency

Even small deviations in mold accuracy can impact vehicle assembly, affecting:

- Door and panel alignment

- Water sealing performance

- Interior noise control

- Structural vibration resistance

Lingfei's precision-controlled molds ensure that each exterior part fits great within the vehicle's frame and integrates smoothly with lighting systems, sealing strips, and functional components. This enables stable, efficient assembly for manufacturers and better performance for end users.

(9) Meeting Global Demand for Three-Wheeled and Four-Wheeled Mobility

As urbanization, e-commerce expansion, and electrification accelerate worldwide, demand for compact mobility solutions—including three-wheeled and four-wheeled EVs—continues to rise across Asia, Europe, Africa, and South America.

These vehicles are vital for:

- Urban delivery logistics

- Short-distance commuting

- Mobile retail and service applications

- Sustainable local transportation

High-quality vehicle exterior molds ensure that manufacturers can bring new models to market quickly, maintain consistent production, and deliver reliable vehicles that meet modern aesthetic and performance standards.

Lingfei Molding's innovation-driven approach—combining modular design, precise machining, and great simulation—positions the company as a strong partner for global vehicle OEMs seeking speed, reliability, and engineering excellence.

Innovation is no longer optional in the rapidly evolving three-wheeled and four-wheeled vehicle markets—it is the core engine of competitiveness. As EV adoption accelerates and product life cycles shrink, manufacturers need mold suppliers who can deliver speed, adaptability, and engineering precision. Lingfei Molding’s modular design philosophy, great five-axis machining capabilities, digital simulation workflows, and strong focus on lightweight materials collectively redefine what is possible in vehicle exterior mold manufacturing.

By enabling faster development, better customization, and higher-quality exterior components, Lingfei Molding empowers automotive and mobility brands to stay ahead of market demand. Whether supporting last-mile delivery vehicles, compact EVs, or new-generation urban mobility platforms, Lingfei is committed to shaping the future of efficient, high-performance exterior mold manufacturing worldwide.