Submit feedback

How Can A Car Center Console Panel Manufacturer Customize Panels?

A Car Center Console Panel is more than just a decorative element; it integrates essential functions between the driver and passenger seats. Switches for lighting, power, and vehicle controls are often combined into a single panel, reducing clutter and improving the ergonomics of the vehicle interior. Using a carefully designed panel can also streamline assembly, prevent component misalignment, and enhance overall interior coordination.

Manufacturers use high-toughness polypropylene (PP) to provide durability while maintaining a lightweight structure. This material performs well in temperatures ranging from -30°C to 70°C, resisting warping, cracking, or deformation over time.

Materials Commonly Used in Car Center Console Panels

Material choice is crucial for durability and aesthetic appeal. Car Center Console Panels are produced using high-toughness engineering plastics, primarily polypropylene (PP). This material offers:

- Strong impact resistance

- Thermal stability across a wide temperature range

- Long-term durability without cracking or deformation

- Compatibility with surface textures, painting, or matte/piano black finishes

Working with a professional Car Center Console Panel Manufacturer ensures that material properties are optimized for both structural stability and interior design needs.

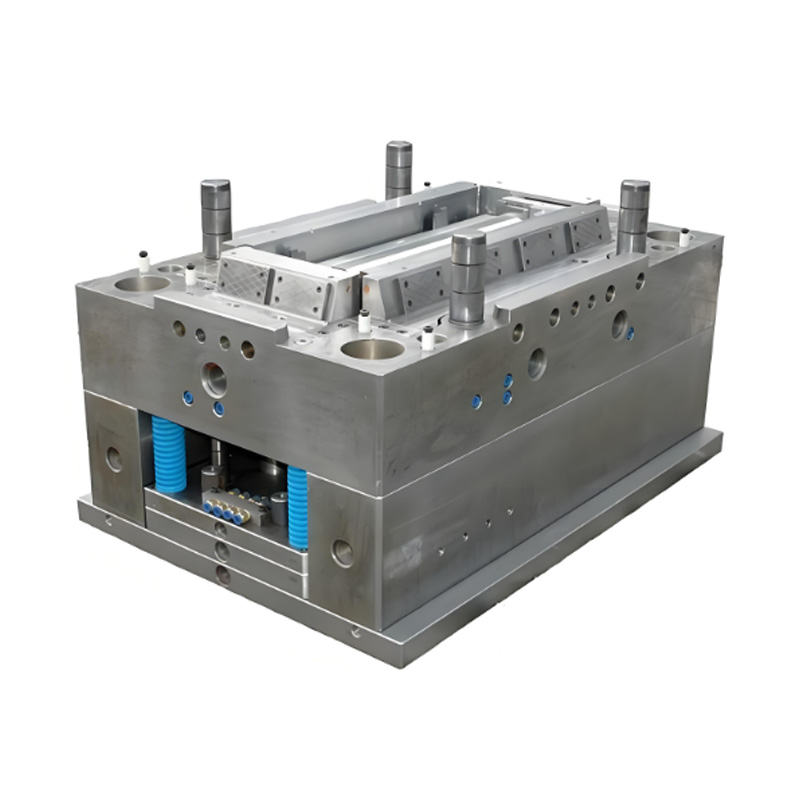

Injection Molding and Panel Manufacturing

Injection molding is the preferred production method for Car Center Console Panels. This technique allows precise shaping of multi-functional panels and ensures repeatable quality across large production runs.

Important Design Considerations:

- Rib reinforcement for structural stability

- Ergonomic positioning of buttons and switches

- Consistent thickness for both strength and weight management

- Compatibility with various vehicle types, from sedans to electric scooters

Thoughtful design ensures that the Car Center Console Panel not only functions well but also contributes to the overall aesthetic of the vehicle interior.

Customization Options for Interior Panels

Manufacturers can customize Car Center Console Panels for different vehicles and design requirements. Injection molds allow for adjustments in:

- Surface color, from matte finishes to glossy piano black

- Integration of additional switches, USB ports, or function buttons

- Compatibility with various vehicle models without altering structural integrity

A reliable Car Center Console Panel Manufacturer can deliver panels that match interior styling while maintaining functional durability.

Durability Testing for Long-Term Use

Panels undergo rigorous testing to ensure performance over time. Stress tests, temperature cycling, and impact assessments are standard for Car Center Console Panels. High-quality materials and precise injection molding ensure that panels maintain their shape, resist cracking, and withstand repeated use.

Integration of Multifunction Components

Modern vehicles demand multifunction integration in a single panel. Car Center Console Panels combine power switches, lighting controls, and functional buttons, which reduces assembly complexity and improves interior consistency. Proper mold design is critical to achieving this integration without compromising structural stability.

A Car Center Console Panel is more than just a decorative element; it integrates essential functions between the driver and passenger seats. Switches for lighting, power, and vehicle controls are often combined into a single panel, reducing clutter and improving the ergonomics of the vehicle interior. Using a carefully designed panel can also streamline assembly, prevent component misalignment, and enhance overall interior coordination.

Manufacturers use high-toughness polypropylene (PP) to provide durability while maintaining a lightweight structure. This material performs well in temperatures ranging from -30°C to 70°C, resisting warping, cracking, or deformation over time.

A Car Center Console Panel integrates multiple vehicle functions, supports interior aesthetics, and maintains long-term durability. By combining high-toughness materials with precise injection molding, manufacturers can produce panels that resist deformation, accommodate multifunction layouts, and offer customizable surface finishes. Partnering with a skilled Car Center Console Panel Manufacturer ensures consistent quality, efficient production, and practical solutions for modern vehicles.