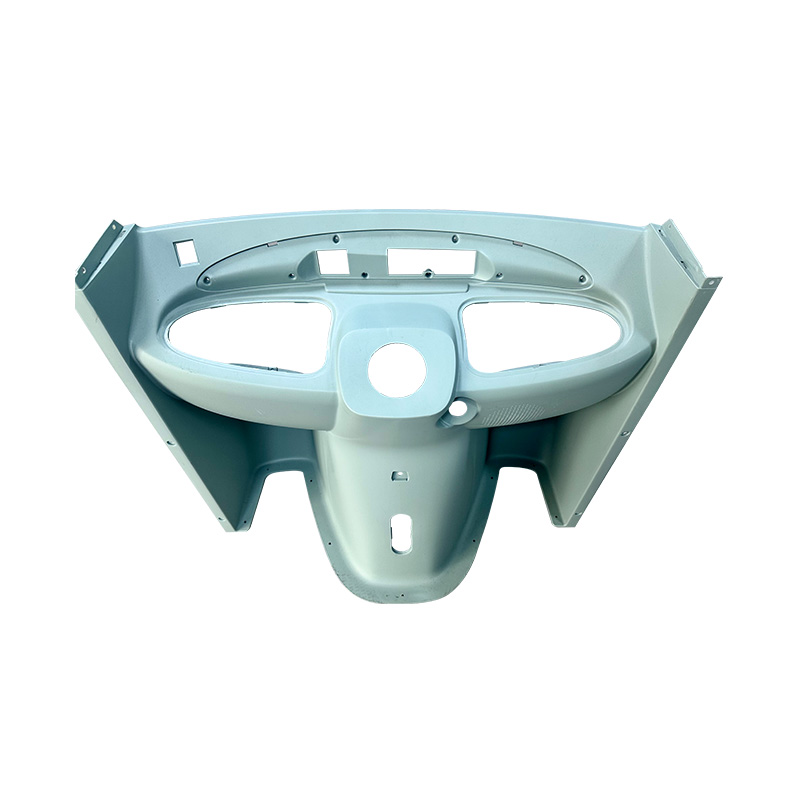

1. What is a Car Center Console Panel?

A car center console panel is the interior component located between the driver and passenger seats. It integrates multiple functions such as lighting controls, power switches, and other function buttons. By combining these elements, it reduces the complexity and mismatch of separate interior components, improving the overall coordination and aesthetics of the center console. High-toughness polypropylene (PP) ensures structural stability, well impact resistance, and weather durability, keeping the panel functional in temperatures from -30°C to 70°C. Additionally, the surface can be customized with paint, textures, or finishes such as matte white or piano black to match interior styling.

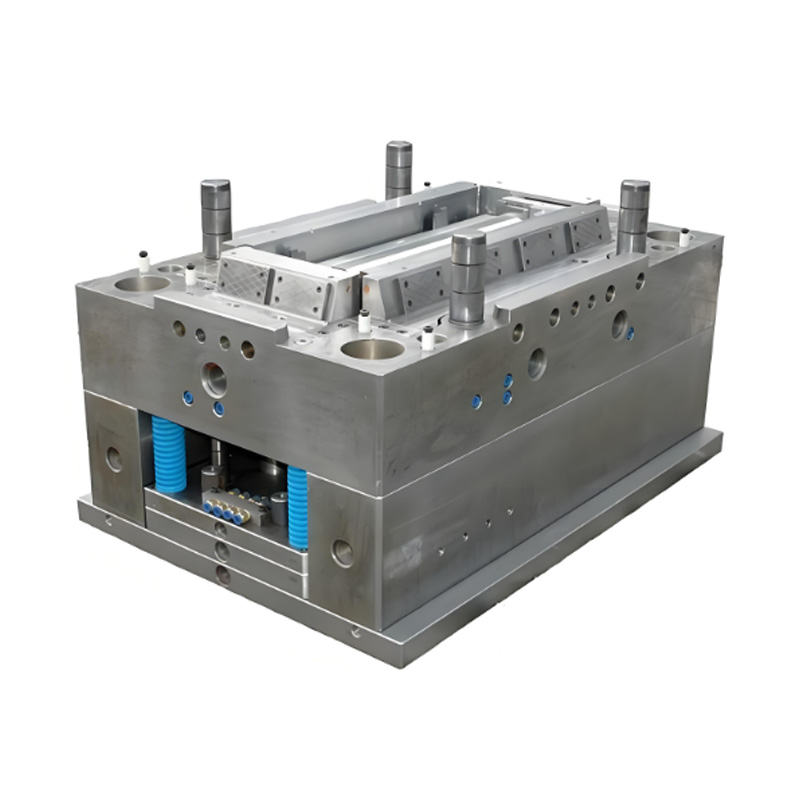

2. How does an Automotive Interior Mold work?

Automotive interior molds are precision tools used to manufacture components like center console panels, dashboards, and trim pieces. These molds shape high-quality engineering plastics such as PP into durable, stable parts that resist cracking and deformation.

Using great molds enables:

- Integration of multiple switches and ports into a single panel.

- Large-scale production with uniform quality and lower costs.

- Smooth surfaces suitable for painting or texturing: This process ensures consistent dimensional accuracy and allows customization of surface finishes to meet different interior design styles.

3. Why use Control Panel Injection Molds?

Control panel injection molds are specifically designed for producing multi-functional interior panels efficiently. Injection molding offers precise shaping, high repeatability, and strong structural integrity. Panels produced in this way can withstand long-term use without deformation or cracking, even under extreme temperature conditions. Key benefits include:

- Multifunctional integration reduces assembly complexity.

- Large-scale production lowers manufacturing costs.

- Allows customized textures and finishes to match interior aesthetics: This makes injection-molded panels ideal for economy sedans, electric scooters, and other vehicles requiring reliable, cost-effective interior solutions.

4. What materials are used for console panels?

High-toughness engineering plastics, primarily polypropylene (PP), are commonly used for center console panels.

These materials provide:

- Impact resistance and weather durability.

- Stability across a wide temperature range (-30°C to 70°C).

- Resistance to deformation, cracking, and long-term wear: The surface of these plastics can be painted, textured, or finished in matte, gloss, or metallic styles to complement the vehicle's interior design. Using PP also supports cost-effective mass production, ensuring panels meet both functional and aesthetic standards.

5. Can panels be customized for different interiors?

Injection-molded center console panels can be tailored to match various interior designs. The molds allow for flexibility in surface color, texture, and finish. Examples include:

- Matte or glossy finishes such as piano black or white.

- Integration of multiple buttons and switches into a single, organized layout.

- Compatibility with different vehicles, from economy sedans to electric scooters: Customization ensures a cohesive and visually appealing interior while maintaining high structural stability and durability.

Car center console panels, made using automotive interior and control panel injection molds, provide multifunctional integration, durability, and design flexibility. Constructed from high-toughness polypropylene, they resist impact, deformation, and temperature changes while supporting customizable finishes like matte or piano black. Injection molding enables consistent quality and efficient production. These panels enhance interior coordination, simplify assembly, and improve vehicle aesthetics, offering a reliable and practical solution for economy sedans, electric scooters, and other vehicles requiring functional and well-designed interiors.