What is a custom front grille for vehicles?

A custom front grille is an exterior automotive modification component designed to replace the original factory grille. It is widely used to upgrade the visual style of a vehicle while maintaining essential functional roles. Compared with standard factory designs, custom grilles allow vehicle owners and brands to express a more distinctive front-end identity.

From a functional perspective, the grille manages airflow into the engine compartment and protects internal components from stones, dust, and road debris. From a design perspective, it reshapes the entire front fascia and can significantly change how the vehicle is perceived on the road.

Typical characteristics include:

- Optimized opening layout for airflow guidance

- Strong structural support for daily driving conditions

- Styling options that align with sporty or premium themes

How does a front grille mold work?

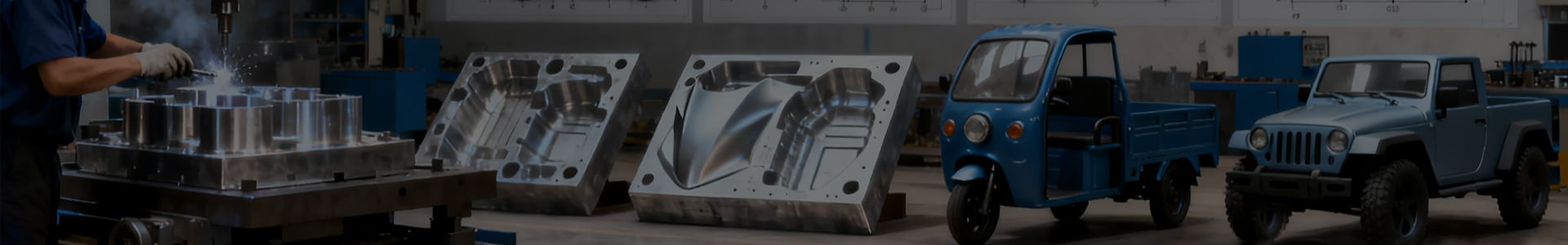

A front grille mold is a specialized injection mold used to manufacture grilles with stable dimensions, consistent appearance, and repeatable quality. During production, molten plastic material is injected into the mold cavity and cooled under controlled conditions to form the final grille shape.

The quality of the mold determines how well the grille fits the vehicle and how refined the surface details appear. Well-designed molds help avoid common aftermarket issues such as uneven gaps or misalignment.

Key mold functions include:

- Accurate replication of grille patterns and textures

- Controlled material flow to prevent warping

- Consistent wall thickness for structural balance

What materials are used in grille molds?

Automotive grille molds are compatible with multiple materials, selected based on cost, performance, and appearance requirements. The many commonly used materials are high-toughness ABS plastic and carbon fiber composites.

ABS plastic is widely applied due to its strong impact resistance and cost efficiency. It is suitable for mass production and daily-use vehicles. Carbon fiber materials are often used for higher-end modifications where weight reduction and premium texture are priorities.

Material-related advantages include:

- Resistance to UV exposure and aging

- Stable performance under temperature changes

- Surface treatments such as carbon-pattern coatings

What designs can automotive modification molds support?

Automotive modification molds for front grilles support a wide range of visual designs to meet different customization styles. Popular grille patterns include honeycomb structures, dot matrix layouts, and carbon fiber-inspired textures.

Design flexibility allows manufacturers to quickly adapt to changing market trends. A simple grille replacement can transform a vehicle from a conservative look to a more performance-oriented appearance.

Common design options include:

- Open or semi-open honeycomb structures

- Dark-toned or high-contrast surface finishes

- Pattern depth variations for visual layering

Are custom front grilles compatible with all models?

Custom front grilles are usually developed based on specific vehicle platforms, but great mold engineering allows adaptation across multiple models within a product range. Mold designers consider mounting positions, curvature, and front-end structure during development.

Compatibility optimization helps ensure smooth installation and stable fixation. Important considerations include:

- Matching original mounting points

- Aligning with bumper and hood contours

- Reducing post-installation adjustments

How do grille molds improve airflow performance?

Some front grille molds are designed with functional airflow optimization in mind, especially for performance or modified vehicles. Enlarged openings or active vent designs help guide more air into the engine bay.

Improved airflow supports better heat dissipation, which is beneficial for vehicles equipped with turbochargers or high-output engines.

Functional improvements may include:

- Enhanced cooling efficiency

- Reduced heat accumulation in the engine compartment

- More stable performance during extended driving

Why choose injection molding for grille production?

Injection molding is widely used for producing automotive front grilles due to its precision and production efficiency. It allows complex shapes and detailed patterns to be formed in a single process while maintaining consistency across large production volumes.

This manufacturing method supports both appearance and structural requirements.

Its advantages include:

- High repeatability for mass production

- Clean surface finish after polishing

- Strong compatibility with various materials