1. What is a car rear bumper used for?

A car rear bumper is primarily designed to protect the rear structure of a vehicle during low-speed impacts. In everyday driving scenarios such as parking, reversing, or minor rear-end collisions, the rear bumper absorbs and disperses impact energy, helping reduce damage to critical components like the trunk floor, rear lights, and frame.

Beyond safety, the auto back bumper also plays a key role in vehicle design. Modern rear bumpers are no longer simple protective parts; they integrate styling elements that define the overall character of a car. A well-designed rear bumper can make the vehicle appear wider, lower, and more dynamic, improving both perceived quality and market appeal.

From a manufacturing perspective, rear bumpers are usually produced using injection molding processes, allowing complex shapes, integrated mounting points, and consistent surface quality. This ensures the bumper performs both structurally and visually across large production volumes.

Key functions of a car rear bumper include:

- Absorbing minor collision impacts

- Protecting rear body panels and structural parts

- Supporting sensors, reflectors, or exhaust trims

- Enhancing rear-end aesthetics and vehicle identity

2. How does an auto back bumper improve vehicle design?

An auto back bumper significantly influences the visual balance and style of a vehicle's rear end. Compared with older designs, modern rear bumpers are shaped with deeper contours, layered surfaces, and wider profiles to match contemporary automotive trends.

Replacing a stock rear bumper with a sport-style or wide-body design can completely transform the vehicle's appearance. For example, when a family sedan is upgraded with a competition-inspired rear bumper, the rear view can shift toward a performance-oriented look, creating a more aggressive and sporty impression without changing the core vehicle structure.

In addition to appearance, auto back bumpers are engineered to integrate seamlessly with:

- Diffuser-style lower sections

- Parking sensors and radar systems

- Decorative exhaust outlets

- Reflectors and lighting elements

This combination of functional integration and visual enhancement makes the rear bumper a critical component in automotive exterior design, not just a protective accessory.

3. What materials are used in car rear bumpers?

Many car rear bumpers are manufactured using high-performance thermoplastics such as polypropylene (PP), ABS, or modified plastic blends. These materials are chosen for their balance of impact resistance, flexibility, lightweight properties, and cost efficiency.

Plastic rear bumpers offer several advantages over metal alternatives. They can deform slightly under impact, reducing damage to the vehicle body, and then return to shape or be easily repaired. They are also suitable for mass production using injection molding, ensuring stable dimensions and surface consistency.

Material selection depends on factors such as:

- Vehicle type and positioning

- Required impact performance

- Surface finish and paint compatibility

- Environmental and durability standards

Through precise mold design and material control, manufacturers can produce rear bumpers that meet both safety requirements and styling expectations.

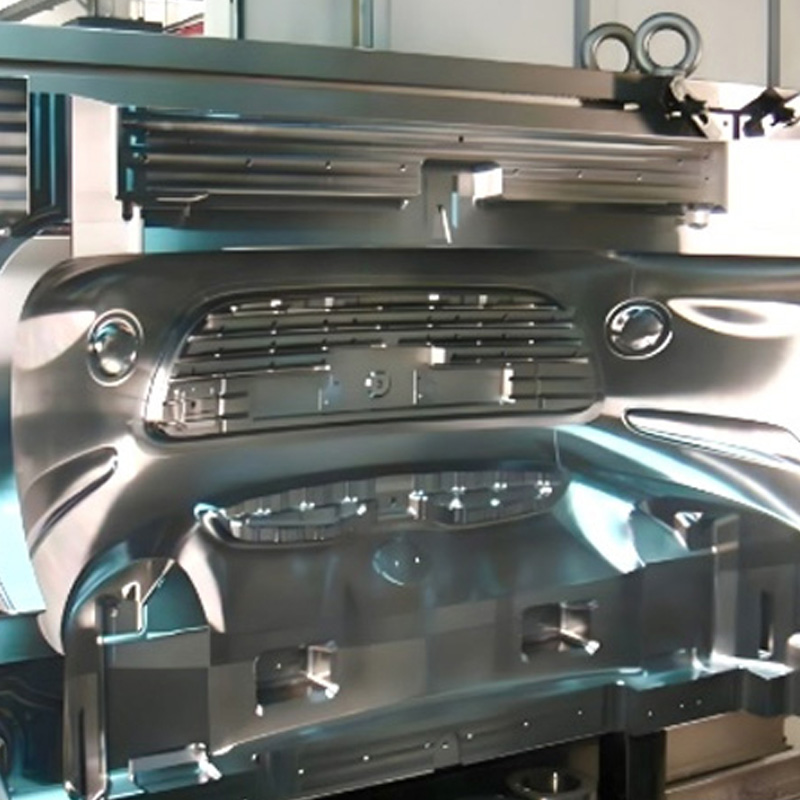

4. What is a car bumper mold?

A car bumper mold is a precision injection mold used to manufacture rear bumper components with high dimensional accuracy and consistent quality. Because rear bumpers are large, complex parts, their molds require great engineering, robust mold structures, and precise flow control.

Car bumper molds are typically designed with:

- Optimized gate and runner systems for uniform filling

- Reinforced mold bases to handle large part sizes

- Accurate surface texturing for exterior finishes

- High durability to support long production cycles

In automotive manufacturing, reliable bumper molds are essential for maintaining efficiency, reducing defects, and supporting consistent branding across vehicle models.

The car rear bumper and auto back bumper serve both protective and aesthetic roles in modern vehicles, while the car bumper mold is the foundation that ensures quality, consistency, and scalable production. Together, they form a critical link between automotive safety, design innovation, and efficient manufacturing, making rear bumper assemblies an essential focus in exterior auto parts development.