Submit feedback

How Does A Car Underbody Protection Plate Protect Critical Components?

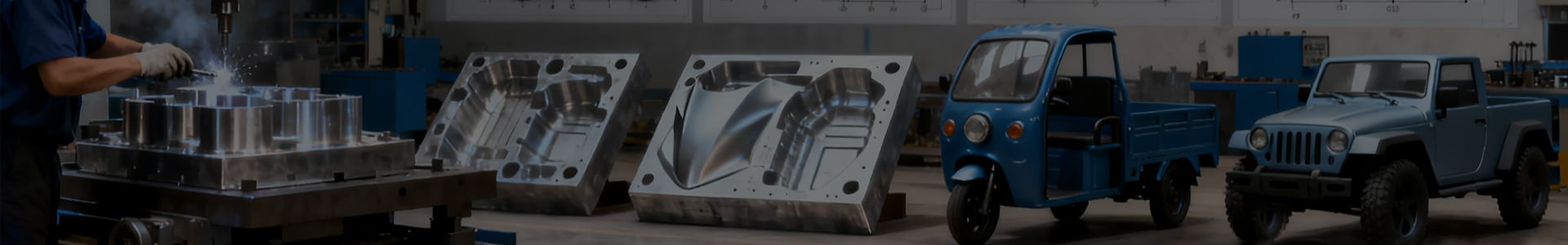

Vehicles constantly face harsh conditions, from road debris to water, mud, and gravel. A Car Underbody Protection Plate serves as a shield for the engine, transmission, and fuel system components. Its primary role is to prevent damage that can cycle to costly repairs or operational downtime. For manufacturers, selecting the right material and production method ensures the plate provides long-term protection without adding unnecessary weight to the vehicle.

Key Materials Used in Car Underbody Protection Plates

Choosing the correct material is essential. Many Car Underbody Protection Plates are made from reinforced plastics, composites, or lightweight metal alloys. Reinforced plastics and composites provide corrosion resistance and reduced weight, which supports fuel efficiency. Metal alloys, on the other hand, offer goodior impact resistance but require careful design to avoid excessive weight.

Material Considerations Include:

- Resistance to abrasion and scratches from road debris

- Heat resistance to tolerate engine and exhaust heat

- Structural strength for impact protection

- Lightweight characteristics to reduce fuel consumption

A skilled Car Underbody Protection Plate Manufacturer can balance these properties to produce a reliable product suitable for mass production.

Manufacturing Methods for Car Underbody Protection Plates

Manufacturing a Car Underbody Protection Plate requires precision moulding techniques. plates are produced using injection moulds for plastics or die-casting moulds for metal alloys. Reinforced sections, ribs, and thickness variation ensure structural stability while maintaining lightweight performance.

Key Factors in Manufacturing:

- Mould design that supports complex shapes

- Proper cooling and curing to prevent warping

- Reinforced ribs for load distribution

- Accurate tolerances for OEM compatibility

A reputable Car Underbody Protection Plate Manufacturer ensures that each batch maintains dimensional consistency, essential for proper vehicle fitment.

Design Features That Improve Protection

The effectiveness of a Car Underbody Protection Plate depends on its design. Plates with rib reinforcement, multi-layer thickness, and strategic coverage zones protect components from impact and debris. Additionally, surface texture can help deflect stones or mud, reducing the risk of surface damage.

Important Design Elements:

- Integrated ribs and thicker sections at high-impact points

- Curved edges to prevent deflection or chipping

- Bolt patterns designed for easy installation and alignment

- Lightweight but rigid construction

Through careful engineering, manufacturers can produce plates that strike a balance between protection and weight.

Reducing Vehicle Maintenance Through Underbody Plates

Installing a quality Car Underbody Protection Plate reduces the frequency of repairs to the engine, oil pan, transmission, and exhaust system. By preventing scratches, dents, and minor collisions, these plates help maintain vehicle reliability over time. This is especially important for off-road vehicles or commercial fleets, where underbody damage is common.

Choosing a manufacturer is crucial. A professional Car Underbody Protection Plate Manufacturer understands the automotive moulding industry, from material selection to production techniques. They can provide solutions that meet OEM standards while ensuring scalability and consistency.

Producing high-quality Car Underbody Protection Plates involves technical challenges, including controlling material shrinkage, preventing warping during moulding, and achieving consistent thickness across complex shapes. Choosing a manufacturer experienced in automotive moulds can mitigate these risks and deliver durable, reliable products.

A Car Underbody Protection Plate is no longer an optional component but an integral part of vehicle design, particularly for commercial and off-road applications. Through careful material selection, precise moulding, and expert design, manufacturers can produce plates that enhance durability, reduce maintenance costs, and extend vehicle lifespan. Working with a trusted Car Underbody Protection Plate Manufacturer ensures that vehicles are protected without compromising performance or weight efficiency.