Submit feedback

How Does An Environmentally Friendly Injection Mold Reduce Production Waste?

Injection molding technology continues to evolve in response to growing environmental concerns and the need for production efficiency. An Environmentally Friendly Injection Mold enables manufacturers to minimize material waste, reduce energy consumption, and lower production costs while maintaining consistent, high-quality output. Modern designs emphasize optimized cavity layouts, enhanced cooling efficiency, and the use of durable mold steels and surface coatings to extend tool life.

Key Benefits of Environmentally Friendly Injection Mold

- Optimized cavity design reduces rejected parts by promoting uniform material flow.

- Energy-efficient heating and cooling systems lower electricity usage, which is particularly important in high-volume production.

- Compatibility with recycled polymers allows companies to incorporate sustainable materials without sacrificing quality.

- Extended mold life through great steel selection and specialized surface treatments minimizes replacement frequency.

- Faster cycle times translate into lower energy usage per part and improved overall efficiency.

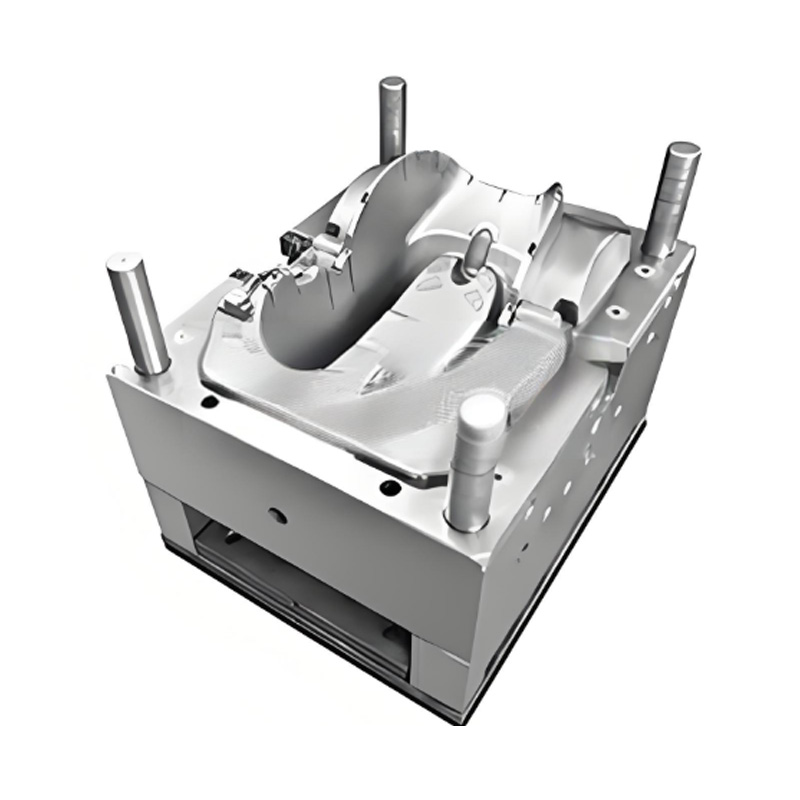

1. Plastic Chair And Stool Mold: Meeting Furniture Manufacturing Needs

The Plastic Chair and Stool Mold is a critical tool for producing ergonomic, durable, and visually appealing furniture. High-quality molds ensure dimensional consistency, structural integrity, and well-surface finishes. This is particularly vital in large-scale furniture production, where repeatability and efficiency are essential for maintaining profitability.

Design Considerations

- Uniform wall thickness ensures structural strength without excess material usage.

- Multi-cavity molds increase production capacity while lowering per-unit costs.

- Surface textures and polish options enhance aesthetics and reduce material sticking during ejection.

- Material versatility allows the use of PP, ABS, or PC to meet varying durability and cost requirements.

Feature Impact on Production

- Multi-cavity mold: Increased output efficiency

- High-precision machining, Consistent dimensional quality

- Textured surface, Enhanced user experience

- Durable mold steel (H13, P20) Longer operational lifespan

The Plastic Chair and Stool Mold is widely used in both commercial and residential furniture manufacturing. For example, outdoor furniture suppliers rely on these molds to produce stackable chairs and stools that withstand repeated handling and varying weather conditions. Multi-cavity designs allow manufacturers to scale production quickly, while flexible material compatibility enables experimentation with recycled plastics or mixed polymer blends.

2. Household Injection Mold: Improving Daily Product Manufacturing

Household Injection Mold is essential for producing daily-use items, including storage containers, kitchen utensils, bathroom accessories, and small appliances. Maintaining consistent quality, durability, and precise geometry is crucial for meeting both client and consumer expectations.

Benefits for Small Manufacturers

- Consistent injection parameters reduce defects, minimize rework, and save material.

- The ability to produce complex shapes allows more innovative and functional product designs.

- Robust mold construction minimizes downtime due to wear or damage.

- Adaptability to multiple polymers enables cost-effective production of products with differing strength or appearance requirements.

Small-scale manufacturers benefit from Household Injection Mold by achieving predictable cycle times, minimizing waste, and lowering operational risk. For example, a producer of plastic food storage containers can use a multi-cavity mold to maintain uniform wall thickness, preventing warping during cooling. The same mold can also accommodate utensil holders or bathroom organizers with minor adjustments to parameters, demonstrating versatility without additional tooling costs.

3. Material Compatibility and Mold Flexibility

Material compatibility is a major factor in the success of injection molding operations. Environmentally Friendly Injection Mold, Plastic Chair and Stool Mold, and Household Injection Mold are designed to work with a broad range of polymers, including reinforced and engineering plastics, without sacrificing quality.

①Standard polymers: PP, ABS, PC, PA, POM, TPU.

②Reinforced plastics: Glass-fiber-reinforced or heat-resistant polymers for enhanced strength and stability.

③Surface finishes: Smooth, textured, or glossy finishes are achievable through specialized mold surface treatments.

④Design flexibility: Multi-cavity or complex-shaped molds reduce the need for multiple tooling sets, saving costs and production space.

Material versatility allows manufacturers to produce a wide variety of products from a single mold. For instance, a Plastic Chair and Stool Mold can produce a high-gloss indoor stool and a textured outdoor chair simply by changing polymer type and injection parameters. Similarly, Household Injection Mold can switch between heat-resistant and standard plastics for different kitchenware or storage items, increasing efficiency and reducing tooling costs.

4. Durability and Maintenance of Injection Molds

The long-term reliability of molds directly affects production efficiency and cost management. Environmentally Friendly Injection Mold, Plastic Chair and Stool Mold, and Household Injection Mold are designed to withstand thousands of production cycles when properly maintained.

①Maintenance Guidelines

- Regular cleaning and lubrication of moving components prevents premature wear.

- Scheduled inspections detect early signs of cracks, wear, or cavity damage.

- Surface treatment or polishing maintains smooth surfaces and reduces material sticking.

②Enhancing Mold Durability

- High-wear-resistant mold steel withstands repeated high-pressure injections.

- Optimized cooling channels minimize thermal stress and cycle-time variation.

- Controlled injection parameters prevent excessive pressure or material flow inconsistencies.

Routine maintenance ensures molds retain dimensional accuracy, consistent product quality, and operational stability. Companies investing in Environmentally Friendly Injection Mold, Plastic Chair And Stool molds, or Household Injection Mold can reliably predict production costs, reduce downtime, and adapt quickly to changing market demands.

5. Practical Industry Applications

Applications of Environmentally Friendly Injection Mold, Plastic Chair and Stool Mold, and Household Injection Mold extend beyond furniture and household products into sectors like automotive, consumer electronics, and industrial equipment.

①Automotive interiors: Molded dashboards, panels, and handles produced using environmentally conscious injection molds.

②Consumer electronics: Durable housings for appliances and devices made with precise household injection molds.

③Commercial and residential furniture: Multi-cavity plastic chair and stool molds support scalable production for hotels, offices, and cafes.

④Electric tricycles and motorcycles: Plastic components such as seats, covers, and storage boxes are produced efficiently using specialized molds.

Adopting great molds helps manufacturers reduce material waste, improve product consistency, and meet environmental and regulatory standards. These molds also enable innovation, allowing new shapes, textures, and multi-material products without significant retooling, increasing both flexibility and profitability.

6. Production Efficiency and Cost Considerations

Investing in high-quality molds impacts not only product quality but also operational efficiency and overall costs. Environmentally Friendly Injection Mold, Plastic Chair and Stool Mold, and Household Injection Mold contribute to measurable improvements in production:

- Reduced cycle times to faster production and lower energy costs.

- Lower defect rates decrease material scrap and rework expenses.

- Durable molds reduce replacement frequency, saving long-term investment costs.

- Flexibility across polymers minimizes the need for multiple molds, reducing storage and tooling costs.

A manufacturer producing household storage containers with a multi-cavity Household Injection Mold can reduce per-unit costs by optimizing injection pressure and cooling time. Similarly, a furniture manufacturer using a high-precision Plastic Chair and Stool Mold can improve output while maintaining uniform surface finish and structural strength.

Molds such as Environmentally Friendly Injection Mold, Plastic Chair and Stool Mold, and Household Injection Mold are indispensable tools in modern manufacturing. They support sustainable production, flexible material use, consistent product quality, and cost-effective operations across multiple industries. By focusing on efficient design, material compatibility, structured maintenance, and production optimization, manufacturers can reduce waste, improve efficiency, and respond to evolving market demands. Investing in reliable, high-performance molds today ensures competitiveness and operational resilience while meeting environmental and client expectations.