Submit feedback

How Do Die Casting Molds Support Stable Industrial Part Production?

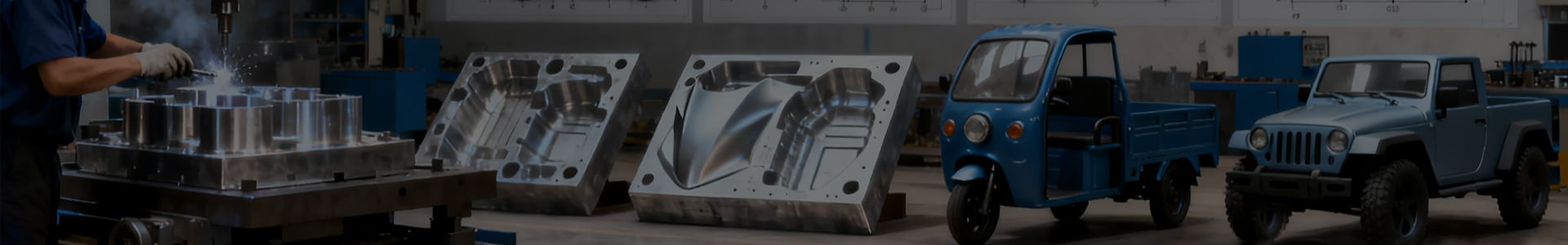

Industrial production relies heavily on precision tooling to maintain consistent quality and high output. For sectors such as automotive, home appliances, motorcycles, and consumer goods, the right molds can make a significant difference in both product performance and manufacturing efficiency. Among these, Die Casting Molds, Plastic Classified Storage Molds, and Plastic Hollow Storage molds play vital roles in modern factories. Each type addresses specific manufacturing challenges, from metal part precision to organized storage solutions and lightweight yet strong plastic components.

1. Role of Die Casting Molds in Metal Component Manufacturing

Die Casting Molds are fundamental for producing metal components that require accuracy, smooth surfaces, and structural integrity. Automotive parts like body panels, door frames, and reinforcement brackets rely on these molds for dimensional consistency. The controlled cavities in Die Casting Molds ensure that molten metal flows evenly, preventing defects such as warping, porosity, or uneven thickness.

The production advantages of Die Casting Molds include:

- High-volume production: Molds support repeated cycles without significant wear, allowing manufacturers to produce thousands of components per day.

- Dimensional accuracy: Properly designed cavities maintain part consistency, which is crucial for assembly line fitment.

- Adaptability: Inserts or minor modifications allow for design updates without rebuilding the entire mold.

Beyond these benefits, Die Casting Molds also contribute to cost predictability. By reducing scrap rates and minimizing downtime, manufacturers can schedule long-term production runs with confidence. In automotive applications, even small deviations in metal panel dimensions can cycle to assembly issues or increased rework. Die Casting Molds address these challenges by providing stable cavity shapes, proper venting, and balanced metal flow paths.

Die Casting Molds are compatible with a range of metal alloys, including aluminum, zinc, and magnesium. This flexibility allows factories to produce components with different mechanical properties without changing the basic mold design. Combined with precision machining and surface treatments, Die Casting Molds ensure smooth, durable metal parts suitable for structural or visible automotive applications.

2. Benefits of Plastic Classified Storage Molds for Organized Products

Plastic Classified Storage Molds are designed for products that require internal partitions or compartments. These molds allow multiple sections to be formed in a single injection cycle, eliminating the need for post-production assembly. This approach is especially useful for storage bins, tool organizers, hardware trays, and industrial components.

The key advantages of Plastic Classified Storage Molds include:

- Consistent compartment structure: Each part comes out uniform in size and alignment, improving product reliability.

- Customizable layout: Molds can be designed with variable slot sizes or removable dividers to match real-world use cases.

- Efficient production: Optimized mold design reduces cooling time, cycle time, and material waste.

- Durability: Proper mold design minimizes stress points, ensuring that dividers and compartments maintain their shape over repeated use.

Manufacturers often face challenges when scaling up production of classified storage products. Without proper molds, internal partitions may deform or misalign, causing customer complaints and returns. Plastic Classified Storage Molds solve this problem by allowing the partitions to be molded as an integral part of the product, improving both durability and user experience.

Plastic Classified Storage Molds are also compatible with a broad range of polymers such as PP, ABS, and PC. Reinforced plastics can be used when additional strength is required, for example, for heavy-duty industrial storage bins. The ability to handle engineering plastics adds versatility for factories producing different grades of storage products without redesigning the mold entirely.

3. Plastic Hollow Storage Mold for Lightweight and Strong Products

Plastic Hollow Storage Mold focuses on creating hollow or semi-hollow structures, reducing material usage while retaining strength. This type of mold is widely applied in consumer goods, packaging, and automotive plastic components. Hollow designs allow for lighter products without sacrificing structural integrity, which is especially important for crates, containers, and housing components for electronics or appliances.

The production benefits of Plastic Hollow Storage Mold include:

- Material efficiency: Hollow parts use less raw material, reducing cost per unit.

- Shorter cycle time: Thinner or hollow structures cool faster than solid parts, increasing throughput.

- Design flexibility: Complex geometries, such as ribbed walls or multi-chamber interiors, can be achieved while maintaining strength.

- Improved transport: Lighter parts are easier to handle, stack, and ship, reducing logistics costs.

Plastic Hollow Storage Mold also helps manufacturers address environmental and cost concerns. Less material consumption translates into lower production costs and reduced environmental impact. In high-volume production, even a small reduction in plastic usage per part can result in significant savings over thousands of units.

From a technical perspective, hollow parts require careful mold design to ensure wall thickness uniformity and avoid defects such as sink marks or warping. Mold cooling channels, gate positioning, and injection parameters must be optimized to maintain quality. When these factors are controlled, Plastic Hollow Storage Mold produces parts that combine strength, precision, and light weight.

4. Material Compatibility and Surface Quality

Both Plastic Classified Storage Molds and Plastic Hollow Storage Mold are compatible with a wide range of plastics, including PP, ABS, PC, PA, POM, TPU, and TPE. Engineering plastics with fiber reinforcement can also be used to enhance durability. Surface treatments of the molds, such as polishing or texturing, ensure high-quality finishes suitable for consumer-facing products.

Die Casting Molds, in contrast, require tool steels selected for wear resistance and thermal stability. Proper mold maintenance and precise machining prevent deformation and ensure long-term performance. High-precision Die Casting Molds contribute to the dimensional accuracy and aesthetic quality of metal components, which is critical in visible automotive or appliance parts.

By selecting the right material combination, manufacturers can tailor product characteristics such as impact resistance, thermal stability, and surface finish. This is particularly important for industrial applications where product failure can disrupt production lines or cycle to costly warranty claims.

5. Ensuring Durability and Performance of Molded Products

Durability is a critical factor for both metal and plastic components. Die Casting Molds produce metal parts with consistent wall thickness, structural integrity, and smooth surfaces, which reduces the likelihood of cracks or deformation during service.

Plastic Classified Storage Molds and Plastic Hollow Storage Mold contribute to durability by ensuring uniform walls and minimizing stress points. By optimizing molding parameters—including injection pressure, cooling rate, and polymer selection—manufacturers can produce products that maintain performance even under repeated use or heavy loads.

Strict quality inspections complement mold design in guaranteeing product reliability. Dimensional measurements, mechanical testing, and visual inspections are common practices to verify that each part meets specifications. These checks help reduce returns and maintain brand reputation in competitive markets.

Durability and Performance Comparison Table

Mold Type Key Durability Feature Production Parameter Optimization Quality Control Methods

Die Casting Molds: Consistent wall thickness, structural integrity, smooth surfaces. Metal alloy selection, cavity design, temperature control, Dimensional measurements, visual inspections, stress tests

Plastic Classified Storage Molds: Uniform walls, reinforced partitions, minimal stress points. Injection pressure, cooling rate, polymer selection, Mechanical testing, visual inspections, and dimensional checks

Plastic Hollow Storage Mold: Lightweight structure with strength, uniform walls. Wall thickness control, optimized gating, cooling channel, Dimensional measurements, drop/impact testing, and visual inspections

6. Integration Across Manufacturing Processes

In modern factories, Die Casting Molds, Plastic Classified Storage Molds, and Plastic Hollow Storage Mold are often used in combination. For example, a single product line may use Die Casting Molds to produce metal structural parts and Plastic Hollow Storage Mold to produce lightweight plastic covers. Storage organizers produced with Plastic Classified Storage Molds may accompany metal hardware components, forming complete kits.

This integration ensures consistent quality across different materials and product types. It also allows manufacturers to streamline assembly, reduce labor costs, and improve overall production efficiency.

7. Long-Term Benefits for Manufacturers

Investing in high-quality molds delivers long-term advantages beyond immediate production efficiency:

- Reduced downtime: Durable molds maintain performance over extended production cycles.

- Flexibility: Inserts, multi-cavity designs, and hollow structures support design variations.

- Cost efficiency: Optimized material use and cycle times lower overall production cost.

- Customer satisfaction: Consistent quality and durability strengthen market reputation.

Die Casting Molds, Plastic Classified Storage Molds, and Plastic Hollow Storage Mold are indispensable tools in modern manufacturing. They solve critical challenges related to material efficiency, part consistency, durability, and production scalability. Properly designed and maintained molds not only improve factory output but also enable manufacturers to adapt to evolving product requirements while keeping costs under control.