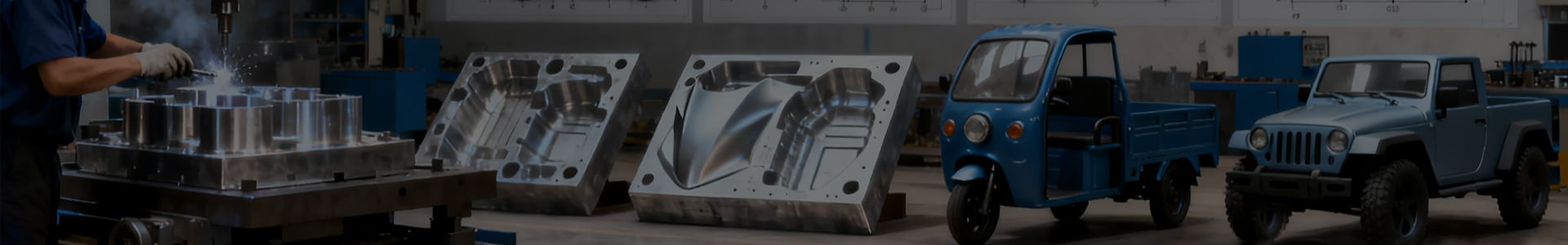

Automotive molds and molded plastic products play a crucial role in modern industrial production, especially in sectors such as automobiles, home appliances, electric tricycles, motorcycles, and consumer goods. From stamping dies for structural vehicle components to high-efficiency multi-cavity plastic molds, each tooling system contributes to high-volume manufacturing with precision and consistency.

1. Auto Parts Molds and Their Supported Processes

Auto parts molds are essential tools used to produce metal automotive components, including body panels such as doors, hoods, and fenders, as well as structural frames and reinforcement parts. These molds rely heavily on stamping technology to achieve high production efficiency.

Key Processes Supported by Auto Parts Molds

Auto parts molds typically support the following manufacturing processes:

- Blanking – cutting raw sheet metal into predefined shapes.

- Drawing – forming deep structural or curved parts.

- Bending and forming – shaping metal to match functional contours.

- Multi-operation stamping – completing several forming actions within one press stroke.

- High-efficiency automated production – ensuring consistency, low labor cost, and stable output.

- Precision surface shaping – essential for visible auto body components requiring high aesthetic accuracy.

These processes enable the rapid and scalable production of complex automotive metal components with reliable dimensional accuracy.

2. Ensuring Design Accuracy for Stamping Dies

Stamping dies for automotive components must meet stringent design accuracy standards to ensure part consistency, structural integrity, and surface quality. The accuracy of the die directly determines the performance and reliability of the final product.

Stamping die accuracy is ensured through:

- Design for Manufacturability analysis to optimize parting lines, draft angles, and material flow.

- Simulation tools are used to predict deformation, spring-back, and forming load.

- Precision machining via high-performance CNC, EDM, and wire-cut equipment.

- Coordinate Measuring Machine inspection for critical die surfaces and profiles.

- Trial production to validate forming results and fine-tune die performance.

This multi-step process ensures the stamping die delivers consistent accuracy and long-term reliability.

3. Material Compatibility of Plastic Molding Dies

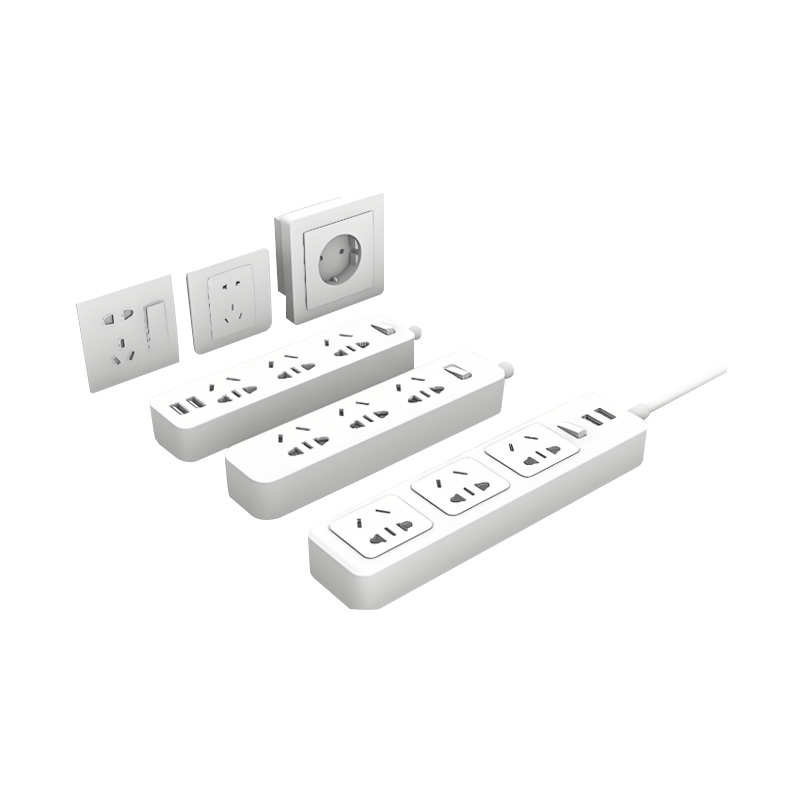

Plastic molding dies are widely used in industries such as home appliances, daily necessities, consumer electronics, industrial supplies, and vehicle plastic parts. Their material compatibility determines the range and performance of molded items.

How Material Compatibility Is Achieved

Plastic molding dies offer good compatibility through:

- Support for a broad range of polymers, including PP, ABS, PC, PA, POM, TPU, and TPE.

- Compatibility with engineering plastics, such as glass-fiber-reinforced materials.

- Optimized mold steel selection, including P20, H13, S136, NAK80, for different temperature and wear requirements.

- Design flexibility allows multi-cavity molds, complex shapes, and precision features.

- High-quality surface treatments, suitable for transparent and high-gloss plastic components.

This versatility makes plastic molding dies suitable for both large and small industrial applications.

4. Ensuring the Durability of Molded Plastic Products

Durability is a key requirement for molded plastic products used in home appliances, consumer goods, electric bicycles, tricycles, and industrial supplies.

Processes That Improve Molded Product Durability

Durability is achieved through:

- Proper polymer selection—engineering plastics offer good toughness, heat resistance, and stability.

- Optimized molding parameters, including temperature, cooling time, and injection pressure.

- Precision mold design to ensure uniform wall thickness and prevent stress concentrations.

- Surface treatments such as texturing, polishing, and plating are used to enhance wear resistance.

- Strict quality inspections, including dimensional measurement, mechanical testing, and reliability checks.

- Controlled post-processing, such as assembly, trimming, and surface finishing, to avoid deformation.

These steps ensure molded products maintain long-term performance in demanding usage environments.

+86-18958510469

+86-18958510469