1. What is a Plastic Product Mold used for?

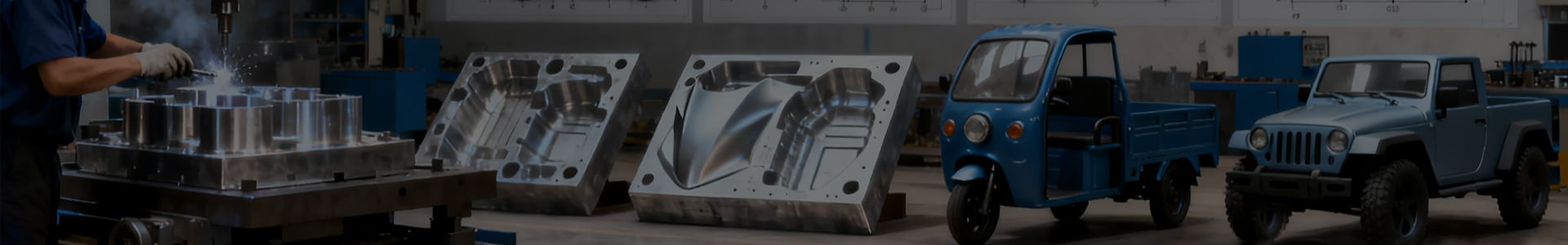

A plastic product mold is a specialized tool used to shape molten thermoplastic materials into finished plastic products with consistent dimensions and surface quality. These molds are designed according to different forming processes, product structures, and production volume requirements.

Plastic product molds are widely used in:

- Consumer goods and daily-use plastic products

- Industrial and mechanical plastic components

- Automotive interior and exterior plastic parts

- Electronic housings and functional enclosures

Core advantages of plastic product molds include:

- High forming efficiency suitable for mass production

- Stable dimensional accuracy across production batches

- Flexible mold design supporting various product geometries

Plastic product molds serve as the foundation of modern plastic manufacturing, enabling scalable and cost-effective production.

2. How does a Plastic Injection Mold improve production efficiency?

Plastic injection molds improve production efficiency by allowing fast, automated, and repeatable molding processes. During injection molding, molten plastic is injected into precisely machined cavities, cooled, and ejected within short cycle times.

Efficiency-related features include:

- Multi-cavity modular design supporting 2–16 cavities

- Short cycle times for small and medium-sized components

- Continuous automated operation with minimal manual handling

Production benefits for manufacturers:

- Higher output per molding cycle

- Lower unit cost at large production volumes

- Consistent product quality with reduced rejection rates

3. Why is precision control critical in Plastic Injection Molds?

Precision control is critical in plastic injection molds because even small dimensional deviations can affect product assembly, appearance, and functionality. High-precision molds ensure that each molded part meets strict design specifications.

Key precision control measures include:

- Use of high-quality mold steels such as S136 and 718H

- Five-axis CNC machining for accurate cavity and core geometry

- Strict tolerance control is suitable for precision component assembly

Quality improvements achieved through precision molds:

- Accurate part fitment with mating components

- Reduced defects such as warpage, flash, and sink marks

- Stable molding performance over long production cycles

4. What materials are compatible with Plastic Product Molds?

Plastic product molds are designed to process a wide range of thermoplastic materials, providing flexibility for different industries and applications.

Common compatible materials include:

- PP and ABS for general-purpose and cost-sensitive products

- PC for high-strength, transparent, or heat-resistant parts

- PA66 with glass fiber for reinforced structural components

- TPE for flexible, soft-touch, or elastic products

Material compatibility advantages:

- Stable processing performance across different plastics

- Optimized mold designs for reinforced or modified materials

- Reliable surface quality under various molding conditions

This broad material compatibility allows manufacturers to adapt quickly to changing product requirements.

5. What makes Food Grade Plastic Molds different?

Food-grade plastic molds are designed specifically for products that come into contact with food or beverages. These molds must meet higher standards for hygiene, safety, and corrosion resistance.

Key features of food-grade plastic molds include:

- Mold steels with good corrosion resistance and cleanliness

- Highly polished cavity surfaces to prevent residue buildup

- Simple and clean mold structures for easy maintenance

Typical food-grade applications include:

- Food containers and packaging components

- Beverage caps, lids, and closures

- Kitchenware and reusable food storage products

Food-grade plastic molds help manufacturers ensure product safety while maintaining efficient and stable production.

6. How do surface treatments improve mold durability?

Surface treatments play a vital role in extending mold service life and maintaining stable molding performance, especially when processing abrasive or reinforced materials.

Common surface treatments include:

- Nitriding to increase surface hardness and wear resistance

- Chrome plating to improve corrosion resistance and surface smoothness

Performance improvements achieved through surface treatment:

- Over 50% improvement in wear resistance

- Reduced mold maintenance and downtime

- More consistent product surface finish

7. Are Plastic Injection Molds suitable for sustainable manufacturing?

Plastic injection molds support sustainable and environmentally responsible manufacturing by optimizing material usage and energy efficiency.

Sustainability-related advantages include:

- High material utilization with minimal waste

- Lower energy consumption per molded product

- Reduced scrap rates through stable process control

+86-18958510469

+86-18958510469