Taizhou Lingfei Mould & Plastic Technology Co., Ltd. specializes in the design, manufacture, and sales of molds for tricycles and four-wheelers, as well as Injection Molding Instrument Panel Housing Interior Support Parts Mold producer in China. Leveraging the industrial advantages of Huangyan District, known as the "Hometown of Moulds in China," the company is committed to providing customers with high-precision, high-quality moulds and comprehensive plastics solutions.

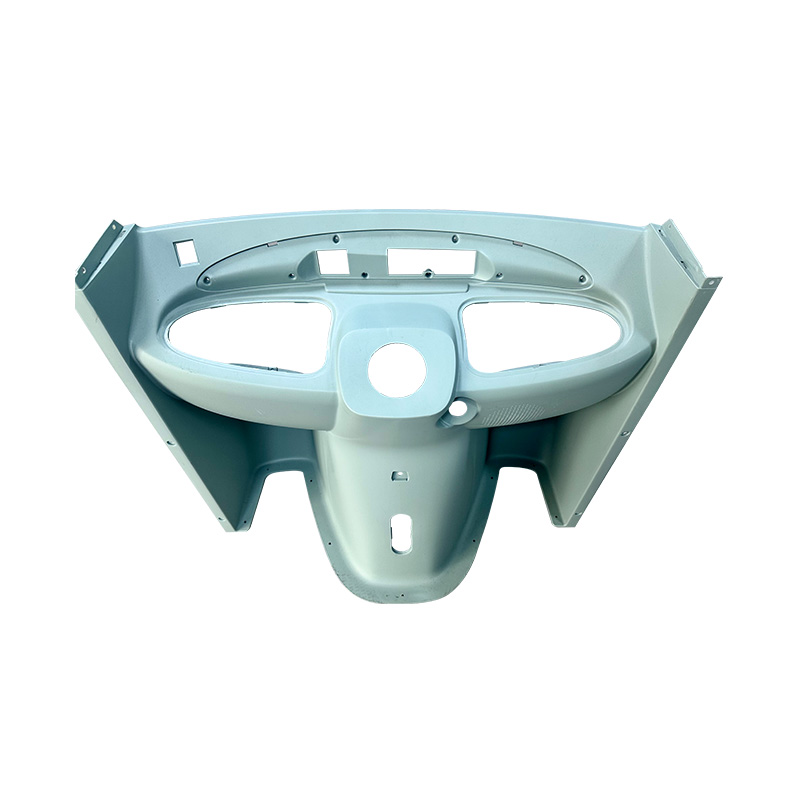

The injection-molded instrument panel housing interior support component utilizes a one-piece injection molding process. Multiple internal reinforcement ribs effectively resist vibration and external impact during driving, ensuring interior structural stability.

Excellent material performance: Made of high-toughness PP engineering plastic, it offers a temperature resistance range of -40°C to 80°C, adapting to extreme high and low temperature environments. It also exhibits excellent aging and UV resistance, making it resistant to deformation and cracking even after long-term use.

Integrated instrument panel mounting holes, air conditioning vent mounting points, and central control module interfaces enable one-stop assembly of various interior functional components, streamlining the production process and improving assembly efficiency.

Having passed rigorous automotive industry durability tests (such as vibration and high and low temperature cycling), its quality meets OEM standards and provides long-term, stable support for the entire vehicle interior.

As the core support housing for the instrument panel, it carries key functional components such as the instrument panel, air conditioning vents, and central control screen. It is a crucial component in the vehicle interior, enabling functions such as driver information display, air conditioning adjustment, and multimedia control, providing intuitive driver information interaction and a comfortable driving environment for drivers and passengers.