1. What Is a Two-Wheeler Mould Used For?

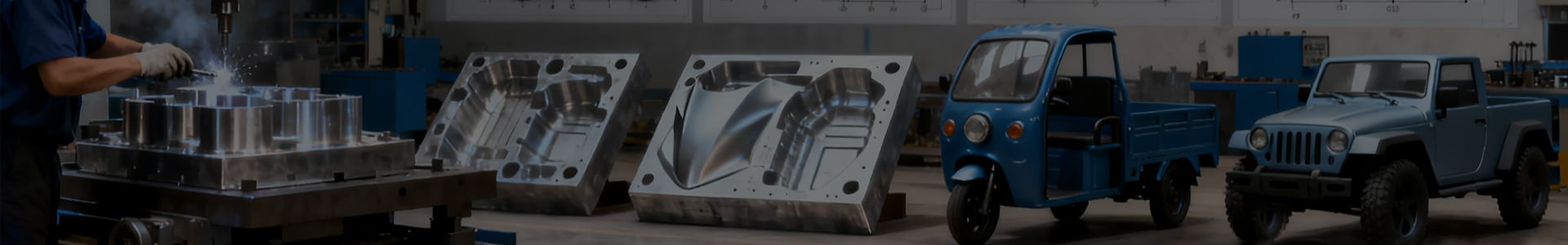

Two-wheeler moulds are specialised manufacturing tools designed for producing components used in motorcycles, electric bikes, and other two-wheel vehicles. These moulds are mainly applied in injection molding processes to form plastic housings, covers, structural panels, and functional parts with high accuracy and repeatability.

Main Applications of Two-Wheeler Moulds

- Plastic housings and exterior covers

- Structural panels and support components

- Functional plastic parts requiring tight tolerances

In modern two-wheel vehicle manufacturing, two-wheeler moulds support large-scale production by enabling continuous, automated operation. Once the mould is installed on the injection molding machine, multiple components can be produced in short cycles, typically ranging from tens of seconds to a few minutes per part.

Production Efficiency Benefits

This high production efficiency is essential for meeting the volume demands of motorcycle and electric bike manufacturers.

- Continuous and automated manufacturing capability

- Short and stable molding cycle times

- Suitability for high-volume production environments

Quality and Consistency Advantages

- Stable dimensional control

- Consistent surface quality

- Reliable part interchangeability

By ensuring uniform wall thickness and controlled shrinkage, th ese moulds help reduce assembly issues and improve overall vehicle quality.

2. How Do Vehicle Injection Molds Support Mass Production?

Vehicle injection molds play a crucial role in supporting mass production for two-wheel vehicles by combining high efficiency with precise control. During injection molding, molten plastic is injected into a closed mould cavity under high temperature and pressure, forming complex shapes that would be difficult to achieve with traditional manufacturing methods.

One-Cycle Manufacturing Capability

One of the main advantages of vehicle injection molds is their ability to produce complex structures in a single molding cycle, including:

- Integrated housings

- Mounting points

- Reinforcement ribs

This integration reduces the need for secondary processing and significantly improves overall production efficiency.

Precision Design for Large Batches

Vehicle injection molds are engineered with strict precision requirements. Key design features include:

- Accurate cavity machining

- Optimised cooling channel layouts

- Balanced runner systems

These elements ensure stable part dimensions and consistent quality across large production batches, even in long-term mass production.

Environmental and Sustainability Benefits

From an environmental perspective, injection molding offers:

- Relatively low energy consumption per part

- High material utilisation and low waste

These characteristics align well with green manufacturing standards and sustainability goals in the vehicle industry.

3. Why Are Two-Wheel Vehicle Molds Important for Precision?

Two-wheel vehicle molds are essential for maintaining precision and versatility in the production of motorcycle and electric bike components. Many parts used in two-wheel vehicles must meet tight tolerance requirements to ensure proper fit, structural integrity, and riding safety.

Versatility Across Component Types

- Decorative exterior cover

- Functional housings

- Load-bearing plastic structures

This versatility allows manufacturers to adapt to different vehicle models and frequent design updates without sacrificing production efficiency.

Precision Control Through Great Design

- Optimised gate placement

- Uniform wall thickness control

- Efficient and balanced cooling systems

These design elements help prevent warpage, sink marks, and dimensional variation during the molding process.

Support for Automated Production

- Stable and repeatable operation

- Reduced manual intervention

- Lower labour costs and quality variation

This automation further enhances production consistency and efficiency.

4. Efficient and Sustainable Two-Wheeler Mould Solutions

Two-wheeler moulds and vehicle injection molds are key enablers of efficient, precise, and sustainable manufacturing for two-wheel vehicles.

Their advantages include:

- High automation levels

- Rapid and stable production cycles

- Capability to form complex and integrated structures

By combining precision control with low energy consumption and high material utilisation, two-wheel vehicle molds help manufacturers achieve consistent quality while meeting environmental and cost-efficiency goals. As demand for two-wheel transportation continues to grow, reliable mould solutions will remain a critical foundation for scalable and competitive vehicle manufacturing.

+86-18958510469

+86-18958510469