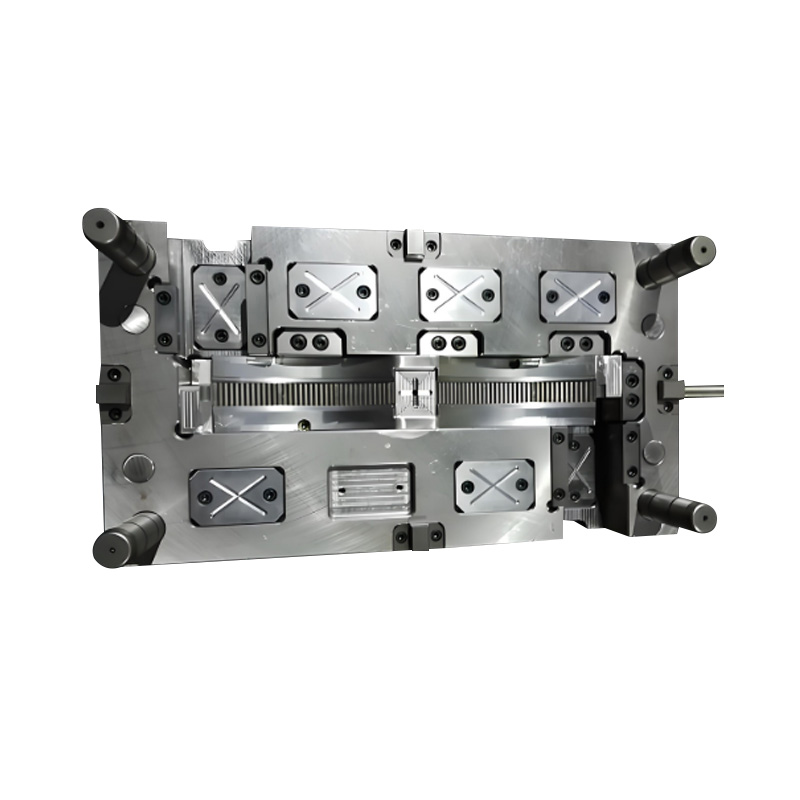

Taizhou Lingfei Mould & Plastic Technology Co., Ltd. specializes in the design, manufacture, and sales of molds for tricycles and four-wheelers, as well as Electric Vehicle Brake Control Handle Injection Mold producer in China. Leveraging the industrial advantages of Huangyan District, known as the "Hometown of Moulds in China," the company is committed to providing customers with high-precision, high-quality moulds and comprehensive plastics solutions.

Key features of the electric bike brake handle: High sensitivity, anti-slip design, lightweight, durable, ergonomic, and made of aluminum alloy. This brake control system for bicycles, e-bikes, and e-scooters is used to apply braking to ensure safe riding.

Powerful and stable braking performance with ample safety redundancy: The core utilizes a roller gear mechanism or opposed twin-cylinder design, paired with ceramic composite brake pads, achieving a coefficient of friction of 0.42-0.45, far exceeding that of ordinary asbestos (approximately 0.38). This allows for rapid transmission of braking force during emergency braking, and combined with the linked braking system, reduces stopping distance by over 30%.

The special drainage groove and labyrinth-style sealing structure maintain over 89% braking efficiency even in 5mm of water, preventing the risk of slipping in rainy weather. The temperature rise is only 23°C after 20 consecutive braking cycles in high temperatures, effectively suppressing thermal decay. Comprehensive and reliable safety features ensure peace of mind: A built-in power-off switch (E-Brake) automatically cuts off motor power when the brake lever is engaged, preventing the risk of rolling or misoperation. The dual-step thread self-locking mechanism allows for brake clearance adjustment with an accuracy of 0.02mm, ensuring consistent braking response.

Some high-end models incorporate a force sensor, allowing for light pulls to decelerate and heavy pulls to park, allowing even novice users to precisely control braking force.

Combining functionality and aesthetics to meet personalized needs, these products offer strong compliance and adaptability, covering a wide range of scenarios and meeting electric vehicle safety standards. Some products are certified for linked braking systems, making them suitable for a variety of vehicle types, including electric bicycles, electric motorcycles, and electric tricycles, whether used as original equipment or as upgrades for older vehicles.