1. What is a car door panel used for?

A car door panel is a key interior component installed on the inner side of a vehicle door. It combines decorative, protective, and functional roles into a single integrated structure. From a user's perspective, the door panel is one of the many frequently touched interior parts, directly influencing comfort and perceived vehicle quality.

Car door panels are designed to cover the internal metal frame of the door while integrating daily-use functions. These typically include window switches, door handles, armrests, speakers, and storage compartments. By organizing these features into a molded panel, manufacturers achieve a cleaner appearance and more efficient assembly.

From a performance standpoint, door panels also contribute to interior noise reduction and vibration control. Through multi-layer plastic structures and optional foam or insulation materials, they help absorb road noise and improve in-cabin comfort. As vehicle interiors continue to evolve, car door panels are no longer simple coverings but carefully engineered interior systems.

Main functions of a car door panel include:

- Interior decoration and surface finish control

- Integration of functional components and controls

- Protection of internal wiring and mechanisms

- Improvement of sound insulation and passenger comfort

2. Why is mold design critical for car door panels?

The quality of a car door panel is largely determined by the automotive panel mold used during production. Mold design affects dimensional accuracy, surface appearance, structural strength, and assembly consistency. Even small design inaccuracies in the mold can cause visible defects or installation problems during vehicle assembly.

A well-designed automotive panel mold ensures uniform wall thickness and stable part geometry. This is especially important for large interior parts like door panels, which are prone to warping or deformation if cooling and material flow are not properly controlled. Mold design also defines how functional areas, such as switch openings and mounting points, are formed.

Key benefits of optimized mold design include:

- Consistent surface texture and appearance

- Accurate alignment with door frames and fasteners

- Reduced risk of sink marks, weld lines, or distortion

- Improved repeatability in mass production

By investing in precise mold engineering, manufacturers can improve production efficiency while maintaining reliable interior quality across different vehicle models.

3. What are automotive interior panel molds?

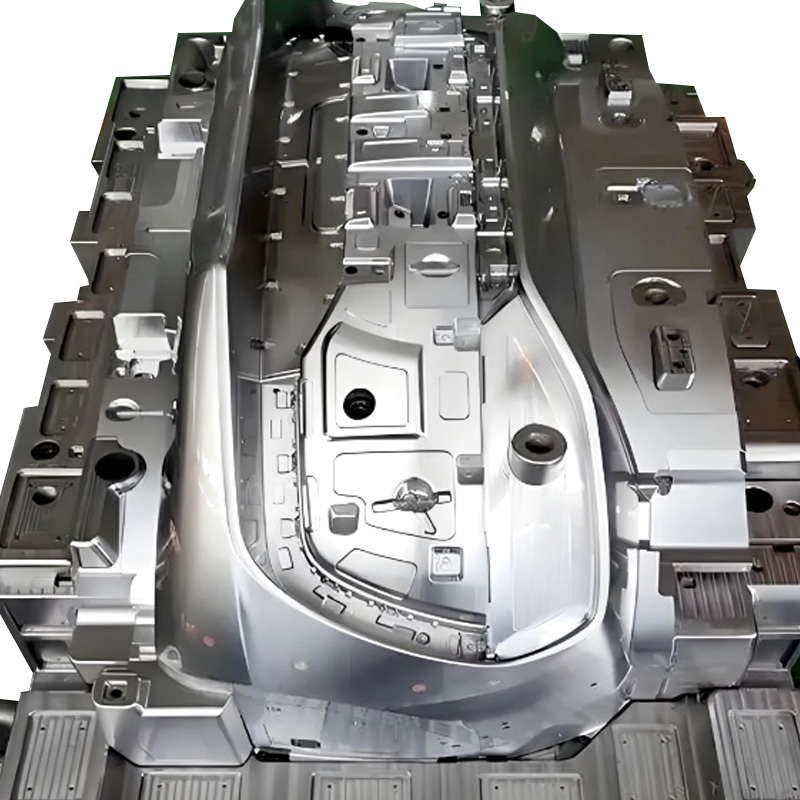

Automotive interior panel molds are precision injection molds used to manufacture plastic interior components such as car door panels, dashboards, console trims, and pillar covers. These molds are engineered to meet strict automotive standards related to durability, dimensional stability, and visual consistency.

Interior panel molds are typically manufactured from high-quality steel to support long production cycles. Their internal structure includes carefully designed cavities, cores, cooling channels, and ejection systems. Each of these elements plays a role in ensuring smooth plastic flow, controlled cooling, and easy part release after molding.

Common characteristics of automotive interior panel molds include:

- High-strength mold steel for long-term use

- Complex cavity geometry matching detailed panel designs

- Optimized cooling systems to control deformation

- Surface texturing to meet interior appearance requirements

These molds allow manufacturers to produce large interior panels efficiently while maintaining consistent quality across thousands of molded parts.

4. How do automotive panel molds support efficient production?

Automotive panel molds are designed not only for part quality but also for production efficiency. By integrating multiple functional features into a single molded panel, they reduce the need for secondary operations and additional assembly steps. This supports streamlined manufacturing and more stable production planning.

Modern molds often allow functional integration, such as reinforcement ribs, mounting clips, and cable routing structures, to be formed during the injection process. This reduces component count and improves overall part consistency. Efficient cooling design further shortens cycle times, helping manufacturers meet production targets.

Automotive panel molds support efficiency through:

- Shorter injection and cooling cycles

- Reduced defect and scrap rates

- Stable part dimensions across batches

- Simplified interior assembly processes

Through proper mold design, suitable material selection, and efficient production processes, manufacturers can produce interior panels that meet modern automotive standards for fit, durability, and appearance. Presenting structured FAQ content like this on product pages not only helps buyers understand mold value but also improves search engine visibility for key automotive molding terms.