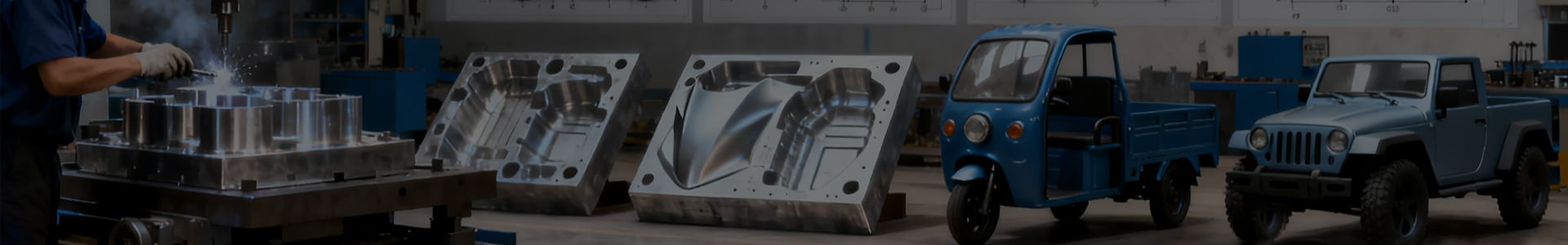

1. Electric Tricycle Mold in Metal Part Manufacturing

Electric tricycles are widely used for logistics, passenger transport, and light-duty industrial applications due to their stability, load capacity, and cost efficiency. Behind the reliable performance of these vehicles lies a critical manufacturing foundation: electric tricycle molds. From metal structural parts to plastic functional components, high-precision molds ensure production efficiency, dimensional accuracy, and long-term durability.

Electric tricycle molds are primarily used in the stamping process to manufacture metal components from sheet materials. Typical stamped parts include frames, brackets, body panels, reinforcements, and load-bearing structures. These components form the mechanical backbone of electric tricycles.

During the stamping process, a metal sheet is positioned between the upper and lower dies. The stamping press applies controlled pressure, forcing the sheet to undergo plastic deformation. The convex and concave geometry of the mold cavity determines the final shape, thickness distribution, and dimensional accuracy of the part.

Working Principle of Electric Tricycle Stamping Dies:

- The stamping press provides a stable and repeatable forming force

- Precisely machined dies guide metal flow during deformation

- Single or multi-stage stamping completes blanking, bending, or drawing

- Finished parts maintain consistent geometry across high-volume runs

2. Why Stamping Dies Are Essential for Three-Wheeled Vehicles?

Three-wheeled vehicle molds play a vital role in achieving production efficiency and structural reliability. Compared with manual fabrication or welding-based forming, stamping dies offer clear advantages in speed, consistency, and material utilization.

- Enhancing Production Efficiency

Stamping dies allow rapid processing of metal sheets, often completing multiple forming operations in a single press cycle. This significantly shortens production time and supports large-scale manufacturing.

Precision die design ensures uniform part thickness, accurate contours, and repeatable dimensions. This consistency is essential for frame alignment, suspension installation, and overall vehicle stability.

- Reducing Production Costs

Stamping offers high material utilization with minimal scrap generation. Combined with low energy consumption per part, stamping dies help reduce overall manufacturing costs for electric tricycles.

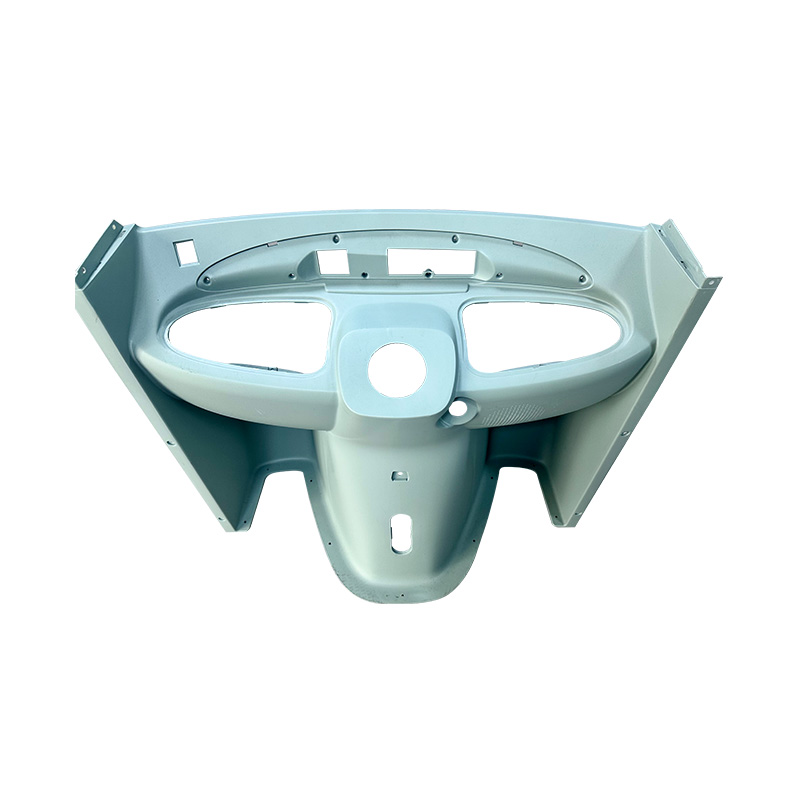

3. Electric Tricycle Injection Mold for Plastic Components

In addition to metal parts, electric tricycles rely heavily on plastic components for both functional and aesthetic purposes. Electric tricycle injection molds are used to produce parts such as exterior covers, dashboards, battery housings, control panels, and protective enclosures.

Injection molding involves heating plastic material until molten and injecting it into a closed mold cavity under high pressure. Once cooled, the material solidifies into a precisely shaped component.

Advantages of Electric Tricycle Injection Molds

- Ability to form complex geometries and integrated features

- High surface quality suitable for visible exterior parts

- Consistent wall thickness and controlled shrinkage

- Stable repeatability for mass production

Injection-molded plastic parts help reduce overall vehicle weight while maintaining sufficient strength and impact resistance. This balance is critical for improving energy efficiency and driving performance in electric tricycles.

4. Combined Role of Stamping and Injection Molds

Modern electric tricycle manufacturing relies on the combination of stamping dies and injection molds. Metal stamping molds provide structural strength, while injection molds contribute lightweight functionality and design flexibility.

Together, these mold technologies enable

- Efficient large-scale production

- Stable part interchangeability

- Improved vehicle assembly accuracy

- Optimized balance between strength and weight

Well-integrated mold solutions also simplify downstream processes such as welding, painting, and final assembly.

Electric tricycle molds are a key factor in ensuring production efficiency, product quality, and cost control for three-wheeled vehicles. Stamping dies enable fast and precise metal forming, while electric tricycle injection molds support the production of lightweight, high-quality plastic components.

+86-18958510469

+86-18958510469