1. What Types of Automotive Parts Moulds Are Commonly Used?

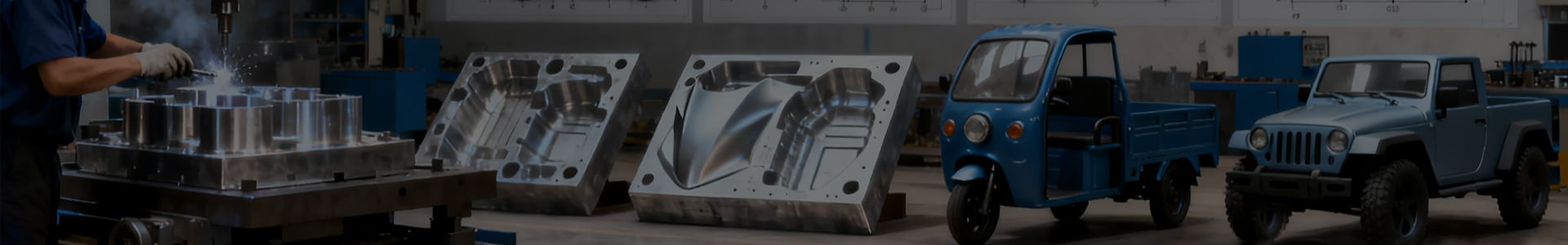

Automotive parts moulds are the foundation of modern vehicle manufacturing, playing a decisive role in product precision, structural reliability, and mass-production efficiency. From exterior body panels to interior functional components, nearly every automotive part depends on a specialized mould designed to meet strict standards.

Common Automotive Parts Mould Types

| Mould Type |

Main Application |

Key Advantages |

| Stamping Dies |

Body panels, frames, and structural parts |

High efficiency, low cost, complex curved shapes |

| Injection Molds |

Dashboards, bumpers, interior panels |

High surface precision, complex geometries |

| Die-Casting Molds |

Aluminum & magnesium alloy parts, Rapid forming |

High-dimensional accuracy |

| Forging Dies |

Gears, connecting rods |

High strength, dense microstructure |

Stamping dies are widely used for sheet metal components such as doors, hoods, and structural reinforcements, enabling fast and repeatable forming in large volumes. Injection molds dominate plastic component production, supporting intricate designs and good surface finishes. Die-casting molds are ideal for lightweight alloy parts with complex internal structures, while forging dies are essential for high-load components requiring maximum strength and durability.

Key Benefits of Automotive Parts Moulds

- Support high-volume OEM production

- Ensure stable dimensional accuracy across batches

- Improve component strength and surface quality

- Reduce per-part manufacturing cost through efficiency

Each mould type plays a critical role in achieving vehicle safety, durability, and consistent quality throughout the production lifecycle.

2. How Does Injection Moulding Improve Car Bumper Strength?

Car bumpers are typically produced using injection moulds due to their large size, complex geometry, and strict impact-resistance requirements. Both material selection and mould structure directly influence bumper performance in real-world driving conditions.

Key Mould Design Features for Car Bumpers

- Long flow paths to ensure even filling of large mould cavities

- Optimized gating systems to eliminate weak or incomplete areas

- Integrated rib and honeycomb reinforcement structures

- Uniform wall thickness to reduce stress concentration

These mould design features ensure that molten plastic flows smoothly and solidifies evenly, minimizing internal stress and improving overall strength.

Main Factors Enhancing Bumper Strength

- Impact-resistant PP or PP-EPDM materials

- Controlled shrinkage and warpage during cooling

- Precision mould temperature management

- Accurate formation of mounting points and interfaces

A well-designed bumper mould not only improves collision protection but also enhances surface appearance, dimensional consistency, and assembly reliability.

3. What Ensures High Assembly Accuracy for Car Dashboards?

Car dashboards integrate airbags, HVAC vents, wiring systems, multimedia units, and structural supports. Even minor dimensional deviations can cycle to assembly gaps, noise issues, or safety risks.

Factors Affecting Dashboard Assembly Accuracy

- Mould Dimensional Precision: Ensures correct geometry for large and complex surfaces.

- Balanced Cooling Channel Design: Prevents uneven cooling that could cause warpage or distortion.

- Plastic Shrinkage Control: Maintains stable part dimensions after moulding.

- Stable Injection Parameters: Ensures consistent cycle timing, pressure, and repeatability.

Benefits of Precision Dashboard Moulding

- Accurate fitment with surrounding interior components

- Reduced assembly gaps and misalignment

- Improved interior appearance, tactile quality, and perceived value

4. Which Materials Keep Automobile Instrument Panels Dimensionally Stable?

Automobile instrument panels must withstand continuous exposure to heat, vibration, and long-term use without deformation. Material selection, combined with precision injection moulding, is critical to maintaining dimensional stability.

Performance Advantages

- Resistance to warping and cracking

- Stable shape under thermal stress

- Support for surface textures, coatings, and anti-glare finishes

These materials, when processed through high-quality injection moulds, ensure long-term structural integrity and consistent appearance.

5. How Are Car Underbody Protection Plates Manufactured?

Car underbody protection plates shield critical vehicle components from debris, impact, water, and harsh road conditions. These parts require robust mould structures and durable materials to perform reliably over long service.

Typical Manufacturing Characteristics

- Injection moulds or die-casting moulds, depending on the material choice

- Reinforced plastic or composite materials

- Thick sections combined with rib reinforcement

Proper moulding ensures that underbody protection plates achieve high durability, dimensional stability, and lightweight performance suitable for modern vehicles.

+86-18958510469

+86-18958510469